Manual Slide Gates For Hoppers

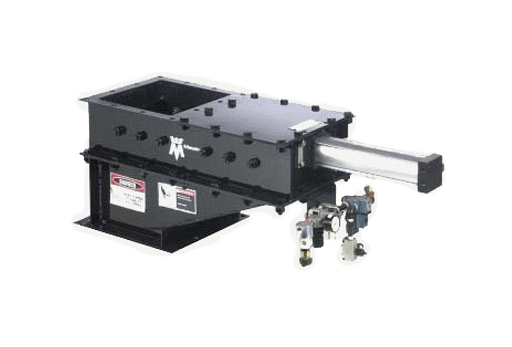

The slide plate can be actuated by manual pneumatic electric or hydraulic means.

Manual slide gates for hoppers. Slide gates consist of a rigid frame mounted to the bottom of the storage device or conveyor. The knife gate and sliding gate valves help control gravity batch unloading when handling dry free flowing materials. Vortex valves serve many industries including chemical cement coal food. Slide gates kase slide gates are used to control the discharge of bulk materials from hoppers bins silos or conveyors.

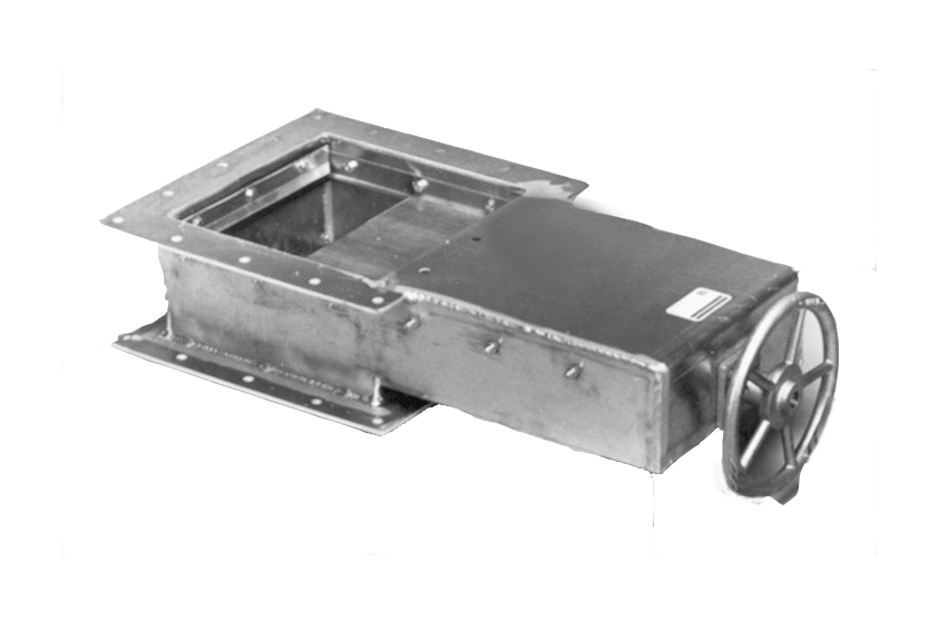

Perform maintenance without taking the valve out of line. Manual operated rack and pinion slide gates are the most common option. Kws slide gates are used to control the discharge of bulk materials from hoppers bins silos or conveyors. A slide plate is located inside the frame that either opens or closes against the flow of material.

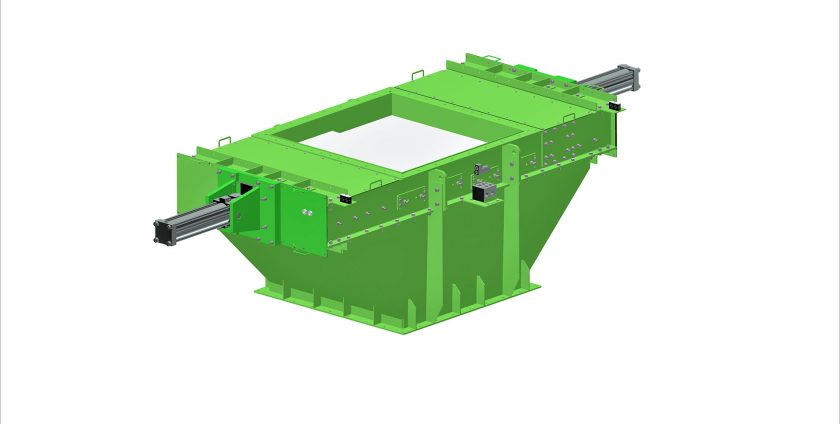

Drain tube minimum 4 in. The purpose of a slide gate below a surge hopper is to shut off material flow so it will not leak to the atmosphere or pressurize the equipment below in most cases. Vortex slide gates are designed and engineered with two main principals in mind. Sight glass minimum 4 in.

Extend the service life of the valve and 2. With manual slide gate 45 or 60 degree hopper. Ideal for handling dry bulk material in gravity flow dilute phase or dense phase pneumatic conveying applications. The inlets and outlets of these gates are square but can be made round by adding square to round transitions.

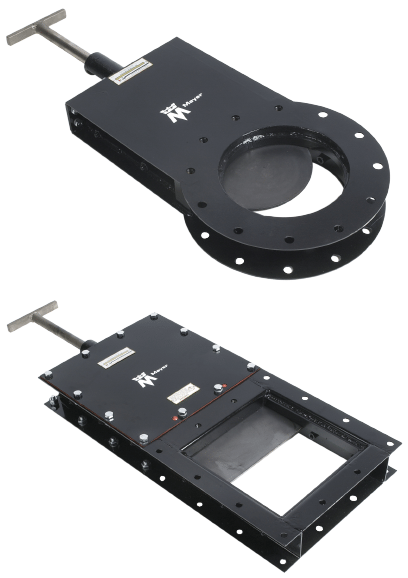

Meyer maintenance slide gates are economical and reliable components used to isolate rotary valves below from hoppers above to control gravity batch unloading. Ideal for dry bulk material handling meyer made knife gates and slide gates are reliable and designed to isolate airlock feeders below from hoppers above. The slide gate control of our plastic cyclone hopper bin is very easy to use and highly effective at controlling the flow of products out of the bin. The dsv slide gate valve has externally replaceable slide gate supports.

One 1 welded carbon steel surge bin leg type with a 45 or 60 degree hopper bottom and a working capacity of between 500 and 10 000 lbs. The best type of slide gates to install below surge hoppers are roller gates for sticky materials or orifice gates if you need to seal differential pressures. These gates deliver a positive shut off of material flow for service or replacement of the system rotary valve without the hopper being emptied. Slide gates consist of a rigid frame with a slide plate located inside that opens and closes against the flow of material.

Unlike other manual slide valves the dsv doesn t use an eccentric cam to support the slide gate.