Makino Cnc Machine Price List

Contact us if you re looking to buy or sell surplus used cnc machines at s m machinery sales.

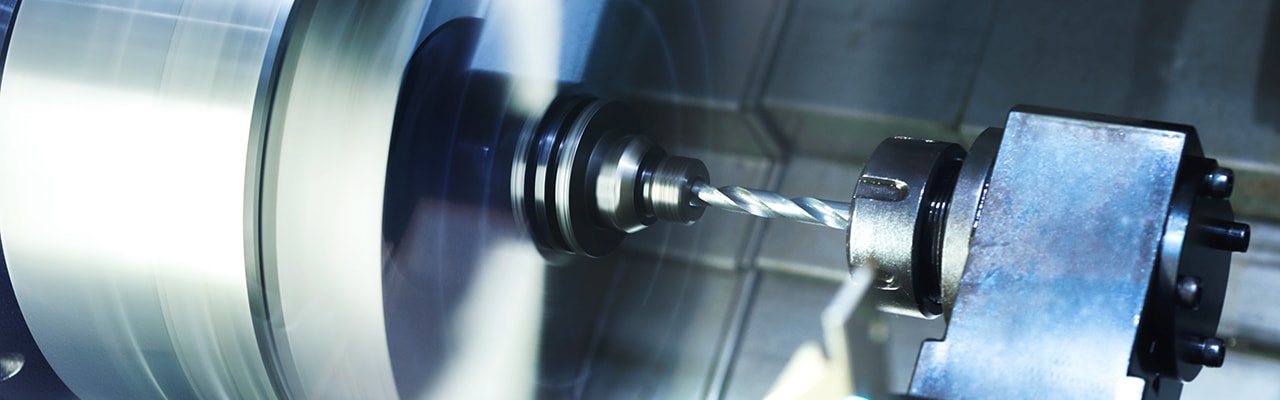

Makino cnc machine price list. Give us a call 586 755 1234. News makino introduces u6 h e a t. 40 4000 rpm. Get a quote today on this v56 before it s gone.

Asia august 2019 the new machine is capable of achieving work piece positional accuracies of 1 micron 0 00004 while providing x y z travels respectively of 650 x 470 x 320mm 25 59. Extreme wire edm utilizing first of its kind 0 016 coated wire technology. Makino combines precision technology with advances in software engineering and automation to unlock productivity and quality on your shop floor. 26 22 2 kw.

This cnc machine is currently located in canada this makino vertical machining center is the only one in stock and available for a limited time. Makino machines combine grinding and milling to reduce part cycle times by up to 75. The innovative haas cl 1 is an ultra compact cnc chucker lathe that comes standard with an 8 station automatic turret making it perfect for high volume production of small precision parts such as those found in the communications aerospace medical and dental industries. In fact there are many well selling cnc machine brands in the world.

Pre owned makino v56 2006 vertical machining center for only 97 500 this vertical machining center has average cutting time and is equipped with a professional 5 control. Z axis travel. Have you heard of these brands. For example taicnc produces about 1000 cnc machines per month more than 90.

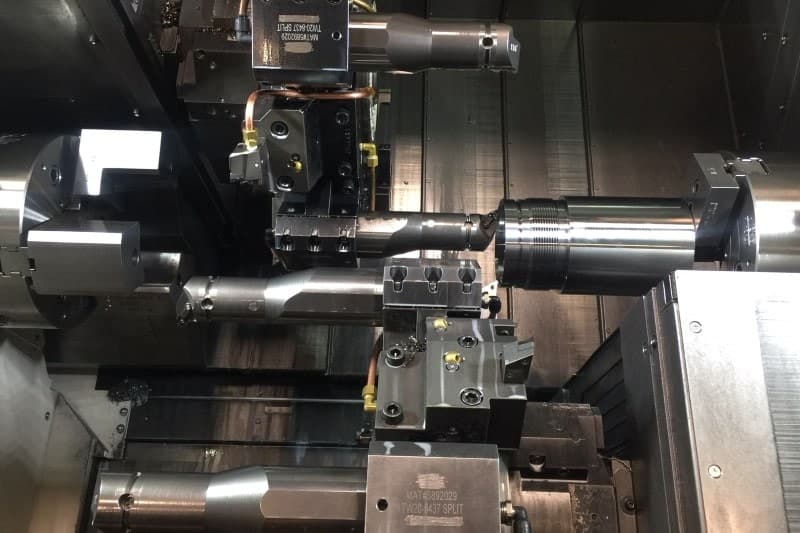

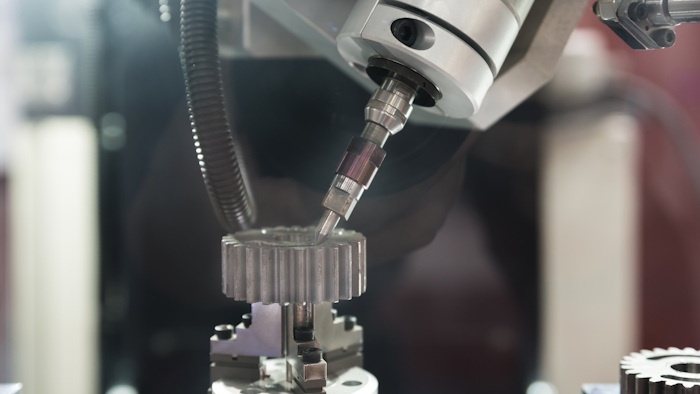

Browse our inventory of makino used cnc machines. Makino a 61nx cnc horizontal machining center fanuc pro 5 control 28 7 25 6 31 5 travels 1100 pound capacity 14k spindle cat40 taper 60 atc 30 hp full 4th axis coolant through spindle hydraulic clamping conveyor 2011. China should be the country with the most demand for cnc machines in the world. In industries like automotive aerospace medical and die mould our machines help you improve performance with every job.

1400 x 520 mm. Makino grinding helps you cut costs by minimizing non cut time setup time and tool changing time.