Making Laminate Bevel Edge With Heat Gun

For a seamless round over edge some manufacturers call it half bull nose edge and others call it waterfall edge you need an adjustable heat gun that can maintain an even temp of 325 degrees to successfully soften the laminate sheet that needs to bend over the min 1 radius routed curved substrate edge.

Making laminate bevel edge with heat gun. Bevel edge countertop trim and countertop edging to match wilsonart and formica brand laminate. The 45 degree angle cut reflects light for a defined border that smartly frames your countertop. Flat back and tongued back. You could even make a beveled edge of your own fasten it to the front then laminate the top.

If you want a fancy ogee bevel or bullnose edge this is something you might want to look into. Bevelled edge laminate flooring. They sell special pre made edges that you can glue onto your countertops. You could also do other profiles as well.

Or thicker up to 1 1 2 in. However the forming temperature will be approximately 170 c 338 f. High quality beveled edging provides a beautiful finishing touch for any laminate countertop design. Heat only the section you need to bend and keep the heat gun moving over that section without focusing on one spot too long.

Bevel on the top edge to expose the wood. The exact temperature to which you must heat your laminate depends on the manufacturer and grade. Laminate edge options decorative edges the difference is in the details. Displaying 1 to 12 of 114 products.

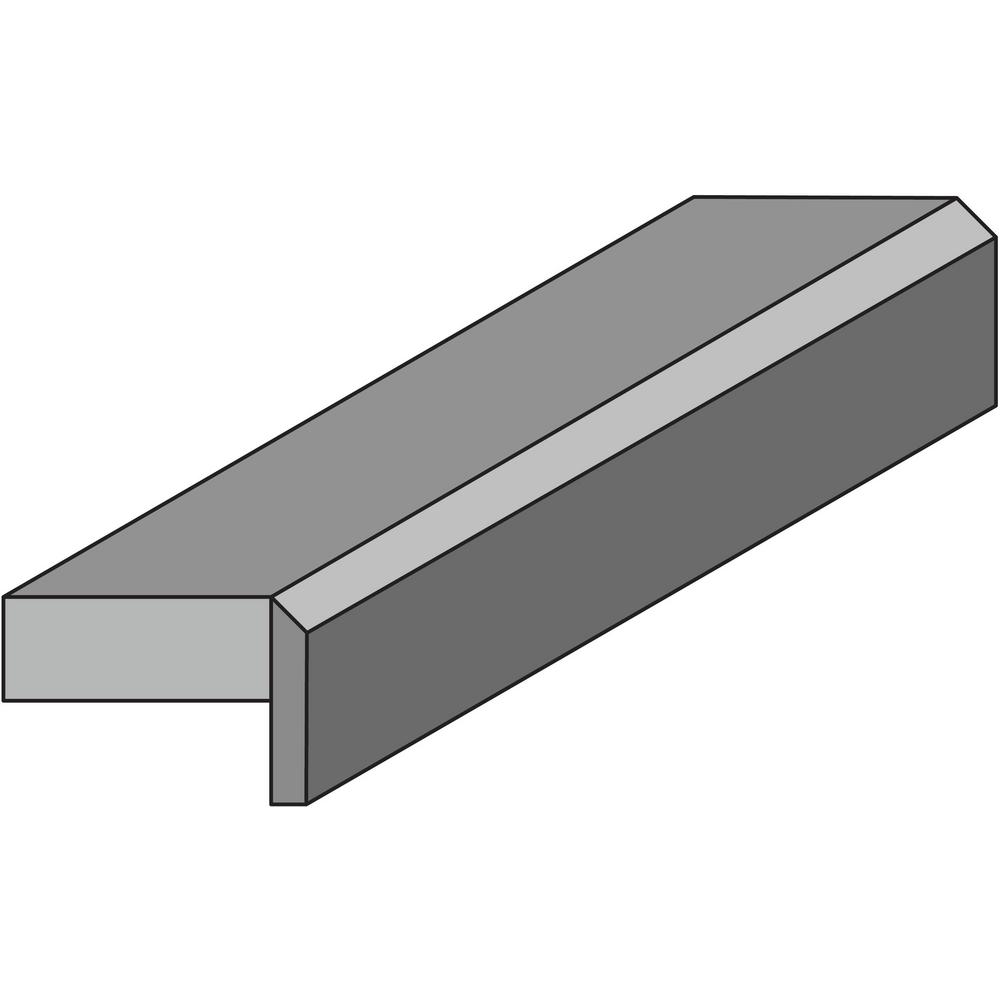

I think it s a great idea and it actually looks easy to do. There is another way to do the edges of a laminate countertop that i just recently found out about. They come in two styles. The flat back molding is glued directly to a standard 1 1 2 in.

Shop our full range of bevelled edge laminates today. Cut off will be included in shipment. Diy instructions for constructing a laminate countertop with beveled edging and an undermount stainless steel sink. Strong crisp angles enhance the solid stone look with a classic look and feel.

A bevelled edge creates an element of dimension to your laminate floor. If too much heat is applied. The edges make each board distinct especially in the light. Thick countertop underlayment and the tongued back fits into a groove routed in the edge of a 3 4 in.

Bevel edge moldings are made of plastic laminate glued to medium density fiberboard mdf. If you remove the back and end splashes then squirt a small amount of acetone under a lifted edge the plastic laminate will literally jump off the substrate before you can set the squirt bottle down.