Machine Planer Blade Angle For Hardwood

With softwoods a slicing action is needed and a hook of 20 to 30 degrees in the head would be needed.

Machine planer blade angle for hardwood. I bought some freud replacement blades some time a go and they are sharpened at 45. The obvious answer is what we all know. With hardwoods a scraping action is needed. The lower you set the angle the sharper your planer blade will be.

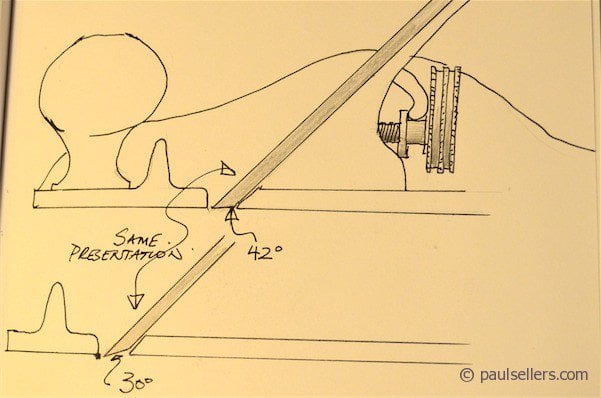

So my q is this to what angle do you have your planer blades ground and why. Given its 12º bed angle you would end up with an angle of cut of 45 degrees 12º 33º 45º the same as on a standard angle plane. Setting the honing guide to 30 degrees requires you to have 38 mm of the planer blade sticking out of the guide. If the blade angle is set properly the planer will produce long curly shavings of wood.

I don t mind any out of balance condition that might exist. Set the direction of cut in the jointer and reduce angle from the tip of the blade. Ensure the straightness of. O 1 steel tolerates more acute sharpening vs.

The low hook angle provides that. I should not be surprised given that we use higher angles for hardwoods with hand planes but i d never given it any thought for planer knives. Both machines cut bevel down so the leading angle of the cut has not changed and there seem to be plenty of clearance in the cutting circle with the 45 blades. If you go with a standard planer head then use a hook angle of 10 to 12 degrees.

The hook angle is the angle built into the cutterhead that creates the cutting action. My dc 380 planer and dj 20 jointer were both delivered with hss blades sharpened at a 30 angle. A 2 or pm blades but the latter two stay sharp longer at a somewhat less acute hone angle. While there is more to consider in edge geometry than just the angle of cut i e durability you could reasonably sharpen the bevel on the iron of a low angle block plane iron to 33 degrees.

Mark the location of the knife on the planner body to align the other blades. A 30 degree angle is ideal for getting a sharp yet durable planer blade. Position jig over blade and cutterhead with the machine unplugged place the jig on the cutterhead and against the chip deflector. Blades honed to more acute angles cut better but stay sharp less long.

The blades are set parallel to the table within 001 from end to end. However the plane s angle of attack surely matters too. As the steel of the jointer or planer blades is too hard it becomes quite tough and time consuming. However the edge will be less durable.

So a bit of googling as to what they should be and i discover that planer knives can vary from 30 to 45 degrees. If the angle is too sharp such as 30 degrees it digs deeper and breaks the shavings into pieces.