Lvl Laminated Veneer Lumber

The lvl billet is then sawn to desired dimensions depending on the end use application.

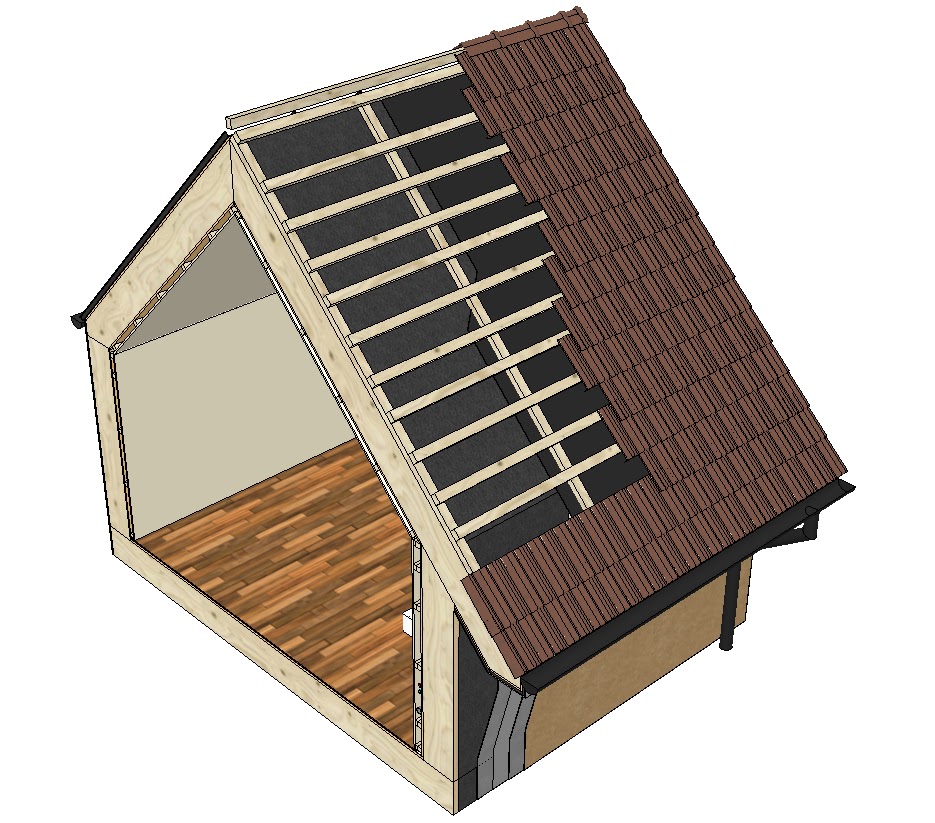

Lvl laminated veneer lumber. Thicknesses range from 1 1 2 inches to 7 inches with depths from 3 1 2 inches to 24 inches roseburg lvl lumber forms beams headers studs columns stair stringers and rimboards in a countless number of homes. Made in a factory under controlled specifications it is stronger straighter and more uniform. Laminated veneer lumber lvl is a high strength engineered wood product used primarily for structural applications. Versa lam laminated veneer lumber lvl beams and headers eliminate twisting shrinking and splitting and deliver flatter quieter floors and structures.

Shop menards for great selection of laminated veneer lumber that can be used as headers or as floor and ceiling beams. It is comparable in strength to solid timber concrete and steel and is manufactured by bonding together rotary peeled or sliced thin wood veneers under heat and pressure. Laminated veneer lumber lvl is an engineered wood product that uses multiple layers of thin wood assembled with adhesives it is typically used for headers beams rimboard and edge forming material lvl offers several advantages over typical milled lumber. Lvl offers several advantages over typical milled lumber.

These products range from sawn lumber and particleboard to laminated veneer lumber. Laminated veneer lumber lvl lvl is a widely used structural composite lumber product. Lvl laminated veneer lumber is a technologically enhanced and improved high strength structural wood based material. Kerto lvl is incredibly strong and dimensionally stable.

Roseburg s lvl division is small but substantial. Lvl offers several advantages over typical milled lumber. Made in a factory lvl is produced under controlled specifications. Laminated veneer lumber lvl is an engineered wood product that uses multiple layers of thin wood assembled with adhesives.

Boises laminated veneer lumber lvl is a product that uses multiple layers of thin wood assembled with adhesives. It is produced by bonding thin wood veneers together in a large billet so that the grain of all veneers is parallel to the long direction. It is typically used for headers beams rim board and edge forming material. Made in a factory under controlled specifications it is stronger straighter and more uniform.

The complex technological process results in a homogenous material with unique performance. Lvl properties significantly exceed those of solid wood glulam and high grade timber. Engineered wood products ewp lvl span and size charts.